Electrical Discharge Machining

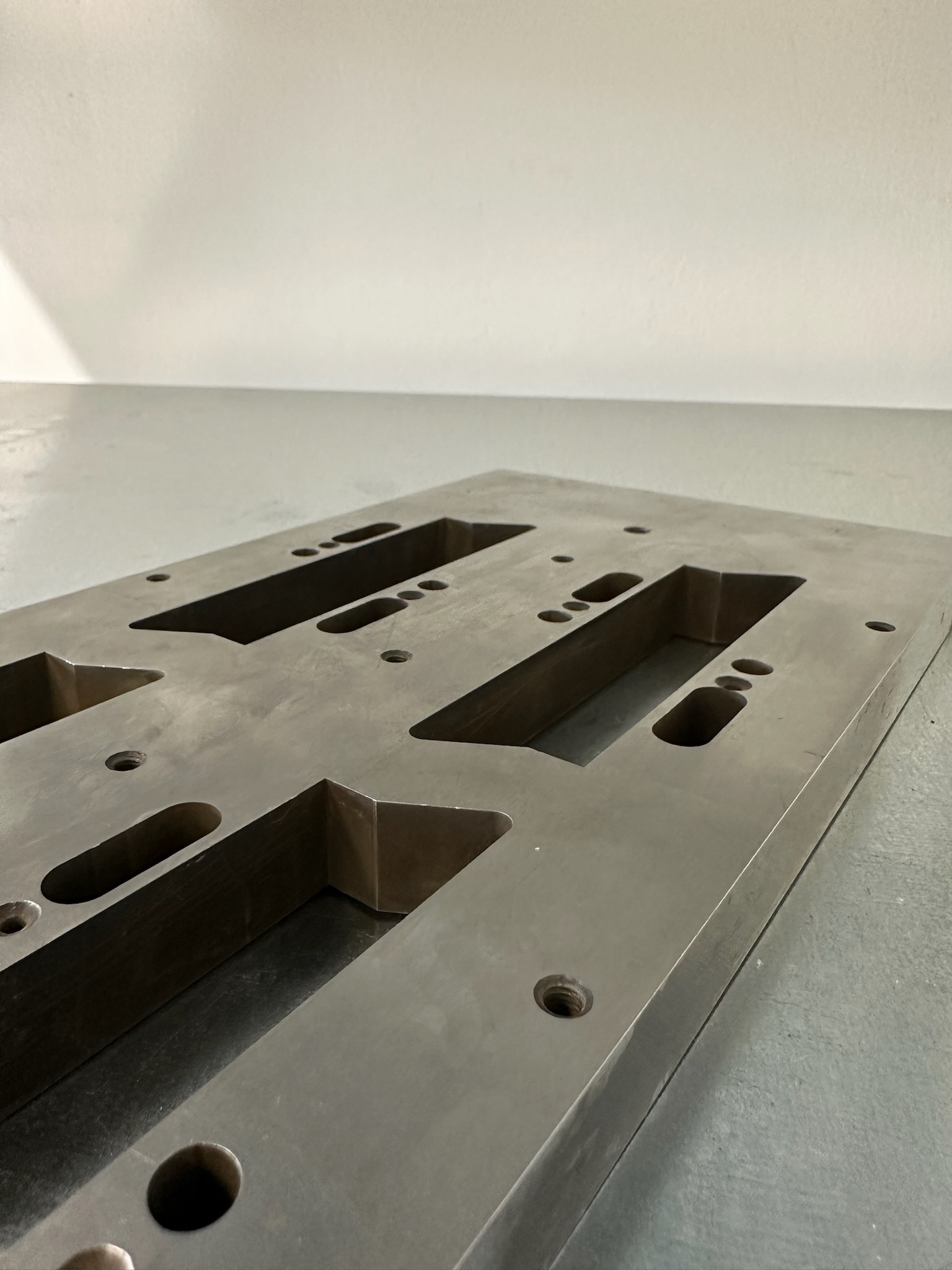

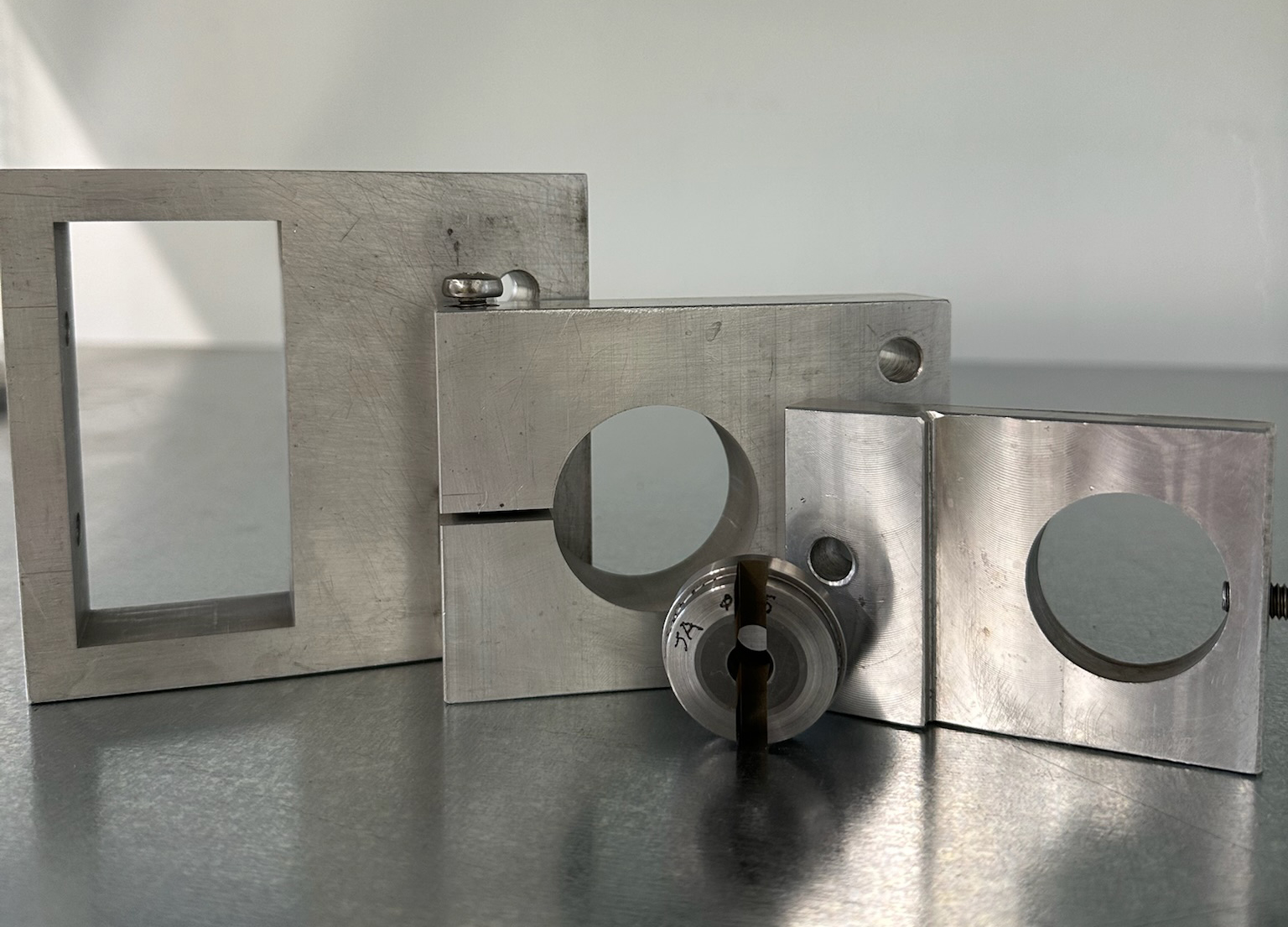

Electrical Discharge Machining (EDM) is a precision manufacturing process that enables the high-accuracy cutting of intricate geometries and hard materials. It is particularly well-suited for toolmaking and the fabrication of fine mechanical components, especially in cases where conventional machining techniques are not feasible.

Advantages of EDM Technology

Electrical Discharge Machining, also known as EDM, removes material from the workpiece using electrical discharges.

This process enables the precision cutting and shaping of extremely hard, heat-treated steels, titanium, tungsten, and other materials that are difficult to machine by conventional means.

One of the greatest advantages of EDM is that it does not require direct physical contact between the tool and the workpiece, thereby eliminating significant mechanical stress or deformation. This is particularly beneficial when machining thin-walled, fragile, or complex-shaped components.

Industrial Applications of EDM

Another significant advantage of this technology is that it can be performed on automated, computer-controlled (CNC) machines, enabling the production of complex three-dimensional shapes and internal cavities. EDM is indispensable in modern industry, particularly in tool and mold making, medical technology, the automotive sector, and the aerospace industry, where precision and superior surface quality are fundamental requirements.